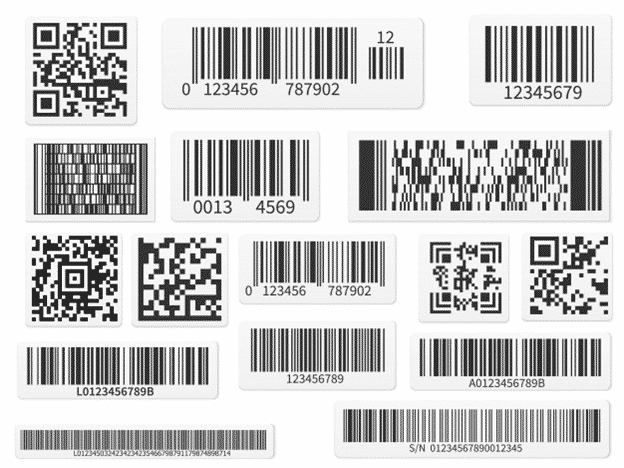

Identify quality defects throughout the manufacturing process.Track and trace products and components throughout the production and supply chain process.Even if there are mechanical damages to the barcode, it is read faster and with less error than a traditional barcode. Applied either on the label of a product, or permanently on the item, the 2D barcode is readable in any direction. Hence, 1D barcodes are known as “linear” and 2D barcodes are also called “area barcodes”.ĢD coding is the future of identification processes, containing more information than a 1D barcode of the same size. While 1D barcodes encode data in one dimension (horizontally), 2D barcodes encode data in 2 dimensions (horizontally and vertically), enabling them to compress more information into a smaller space. As a result 2D barcodes were invented in the late ‘80’s as a way to encode more data into a smaller space. 1D barcodes are not space efficient they get longer as more data is encoded. A barcode scanner analyses the wide bars, narrow bars and spaces in between to extract the information. Allow Fairfield to explain auto identification data capture along with the differences between 1D and 2D barcoding, and the advantages and applications for which these technologies are used.ġD barcode uses a wide base and narrow bars to encode information. Deciding which one is right for your business can be a difficult task. Fairfield provides a vast selection of data collection systems, including 1D and 2D barcodes, each specifically designed to service your individual business needs.īarcode systems and scanning technology are constantly evolving, providing industries with more choices in data capture solutions. Auto ID technology and barcode systems provide an array of benefits including operational efficiency, better customer service and improved visibility and accuracy of key business information to management. They are widely used to implement Auto ID Data Capture systems that improve the speed and accuracy of computer data entry. Even if there are mechanical damages to the barcode, it is read faster and with less error than a traditional barcode.īarcode systems feature as part of our everyday lives – on your mobile phone, plane boarding passes, parcels delivered to your door and patient wristbands.

2D coding is the future of identification processes, containing more information than a 1D barcode of the same size. Barcodes are widely used to implement automatic identification data capture systems that improve the speed and accuracy of computer data entry. Originally barcodes stored data in widths and spacings of printed parallel lines (1D Barcodes), but today they also come in patterns of dots, concentric circles, and text codes hidden with images (2D Barcodes). A barcode is a machine readable representation of information.

0 kommentar(er)

0 kommentar(er)